Panasonic placement machine NPM-DX product parameters Parameters

Model name | NPM-DX | |

Substrate size * When selecting long conveyor belt | Double track | L50mm x W50mm ~ L510mm x W300mm |

Monorail | L50mm x W50mm ~ L510mm x W590mm | |

Substrate replacement time * When selecting short conveyor belt | L275 mm or less | 2.1s |

L275 mm over ~ L460 mm below) | 4.8s | |

power supply | Three-phase AC 200, 220, 380, 400, 420, 480V 5.0 kVA | |

power source | Minimum 0.5MPa, 200L/min (ANR) | |

Equipment size | W1665mm x D2570mm x H1444mm | |

weight | 3600kg (main body only, varies depending on optional components) | |

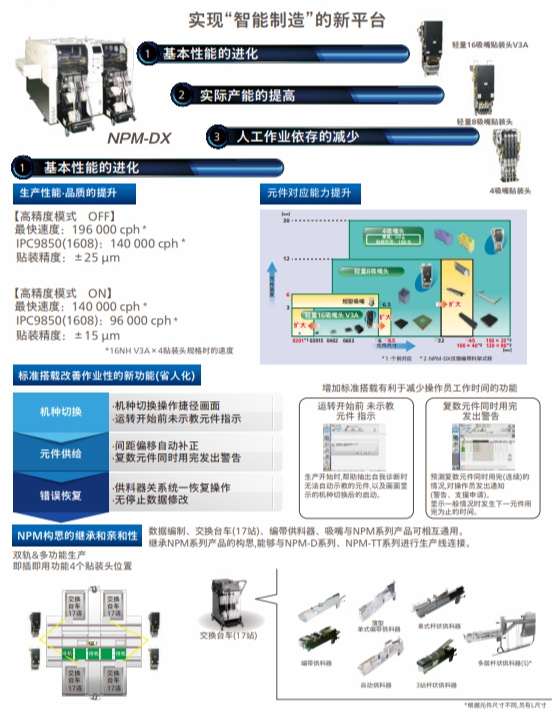

placement head | Lightweight 16-nozzle placement head V3A (per placement head) | Lightweight 8-nozzle placement head (per placement head) | 4 nozzle placement heads (per placement head) | ||||

High-precision mode (OFF) | High-precision mode (ON) | High precision mode (OFF) | High-precision mode (ON) | High precision mode (OFF) | High-precision mode (ON) | ||

Fastest speed | 49,000cph (0.073s / chip) | 35,000cph (0.103s / chip) | 24,000cph (0.150s / chip) | 18,000cph (0.200s / chip) | 8,500cph (0.655s / chip) 8,000cph (0.847s / chip) | 6,500cph (0.655s / chip)

| |

Mounting accuracy (Cpk ≧1) | ±25μm/chip | ±15μm/chip | ±25μm/chip ±25μm/QFP | ±15μm/chip | ±25μm/chip ±20μm/QFP | ±15μm/chip | |

Component size (mm) | 0201 chip/03015 chip 0402 chip ~ L 8.5 × W 8.5 × T 3 / T 6 | 0402 chip ~ L 45 × W 45 or L 100 × W 40 × T 12 | 0603 chip ~ L 120 × W 90 or L 150 × W 25 × T 30 | ||||

Component supply | braid | Braiding width: 4 / 8 / 12 / 16 / 24 / 32 / 44 / 56 mm | Braiding width: 4 ~ 56 / 72 / 88 / 104 mm | ||||

4, 8 mm tape: Max. 136 varieties | |||||||

Rod-shaped | Max.32 varieties (single rod feeder) | ||||||

Panasonic’s next-generation assembly manufacturing (X series) concept :

Autonomous functions enable stable operation

Autonomous production line control

APC system, automatic recovery option

Save labor and improve operation rate

Centralized control

Workshop management system, remote operation option

Suppressing unevenness in manual work

Navigation, automation small products

Feeder preparation navigation, component supply navigation, automated small products

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen